Check Cable Integrity: Conduct a comprehensive visual inspection of the entire length of the coaxial cable. Look for any physical damage such as cuts, punctures, abrasions, or compression marks. These issues can compromise the integrity of the cable's shielding and dielectric, leading to signal leakage, increased attenuation, or even complete signal loss. Pay close attention to areas near connectors and bends, as they are more prone to mechanical stress during installation or movement.

Verify Connector Quality: Inspect the connectors on both ends of the coaxial cable meticulously. Ensure that they are securely attached to the cable and that the crimps or solder joints are robust and properly executed. Poorly crimped connectors or loose fittings can introduce impedance mismatches, which in turn cause signal reflections. Verify that the connectors are of high quality and rated for the frequency range and power levels of the RF signals being transmitted. Consider using connectors with gold-plated contacts for improved conductivity and corrosion resistance.

Verify Connector Compatibility: Confirm that the connectors used are compatible with the type of coaxial cable employed and that there are no adapters or transitions that could introduce additional losses or impedance mismatches. Check for proper mating and ensure that connectors are clean and free of any debris, oxidation, or contamination that could degrade electrical contact. Use cleaning tools and solutions designed specifically for RF connectors to maintain optimal performance.

Inspect Installation: Evaluate the installation path and conditions of the coaxial cable. Ensure that it follows recommended installation practices to minimize signal loss and interference. Avoid sharp bends with a radius smaller than the manufacturer's specified minimum bend radius, as these can cause signal attenuation and potentially damage the cable over time. Secure the cable away from sources of electromagnetic interference (EMI), such as power lines, motors, fluorescent lights, and other RF equipment, to reduce the risk of signal degradation.

Check for Moisture or Corrosion: Examine connectors, cable ends, and any exposed portions of the coaxial cable for signs of moisture ingress, corrosion, or oxidation. Moisture and corrosion can increase the resistance in the cable assembly, leading to higher insertion loss and reduced signal quality. Use weatherproofing techniques such as waterproof tape, heat shrink tubing, or weather-resistant boots to protect connectors and cable ends, especially for outdoor installations exposed to environmental elements.

Measure Signal Loss: Utilize a network analyzer or cable tester equipped with RF measurement capabilities to quantify insertion loss (attenuation) along the entire length of the coaxial cable. Perform measurements at different frequencies within the operating range of the cable to capture frequency-dependent losses accurately. Compare the measured insertion loss values against the manufacturer's specifications and industry standards to assess whether they meet performance requirements. Document and analyze measurement data to identify any anomalies or deviations from expected values.

Consider Cable Length: Evaluate the length of the coaxial cable relative to the requirements of the application. Excessively long cables can introduce additional insertion loss, particularly at higher frequencies, due to signal attenuation along the transmission path. Use signal loss calculations based on the cable specifications and system requirements to determine the maximum permissible cable length without compromising signal integrity. Consider using low-loss coaxial cables with superior electrical properties and lower attenuation rates for longer transmission distances or applications requiring minimal signal loss.

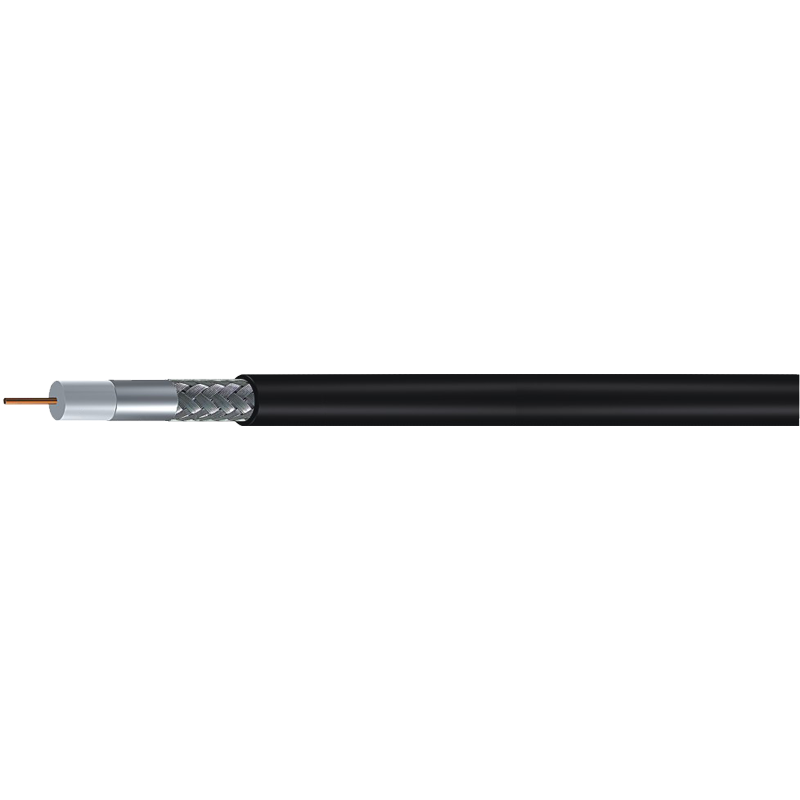

LMR200 50 Ohm High Frequency Low Loss Flexible Coaxial Cable