Maintenance requirements and recommendations for coaxial cables like KX6 and KX7 in CCTV systems typically revolve around ensuring the cables' integrity and performance over time. Here are some general maintenance guidelines:

Regular Inspections:

Physical Integrity Assessment: Conduct meticulous visual inspections of the entire cable length, checking for any signs of wear, tear, cuts, abrasions, or deformities. Regularly inspect the outer sheath and inner conductors for anomalies.

Connector Examination Protocol: Institute a thorough examination of all connectors, scrutinizing for corrosion, oxidation, or any physical damage. Employ magnification tools if necessary to ensure a detailed inspection. Establish a schedule for routine connector maintenance and cleaning.

Environmental Considerations:

Weatherproofing Strategies: Employ advanced weatherproofing techniques, including the application of sealants and specialized cable jackets, to fortify cables against moisture, humidity, and UV exposure. Perform periodic weather resistance tests to validate ongoing protection efficacy.

Temperature Management Measures: Develop a comprehensive strategy for temperature control, implementing insulating materials where needed and incorporating climate-specific cable types to withstand extreme temperature variations.

Secure Connections:

Advanced Connection Checks: Utilize advanced testing equipment, such as reflectometers and time-domain reflectometers, to assess the impedance and reflectance of connectors. Implement a stringent torque verification protocol to ensure connectors are tightened to precise specifications.

Cable Management:

Precision Organization: Implement an intricate cable management system, utilizing cable trays, raceways, and purpose-built conduits. Employ cable ties and clamps with precision, adhering to the cable manufacturer's guidelines for bend radius and stress relief.

Elevation and Routing:

Strategic Elevation Planning: Develop elevation plans that strategically position cables above ground level, factoring in potential hazards and pedestrian traffic. Implement cable routing solutions that prioritize both safety and signal integrity.

EMI/RFI Mitigation: Conduct a comprehensive electromagnetic interference (EMI) and radio-frequency interference (RFI) assessment, implementing shielding techniques and rerouting strategies to minimize potential interference sources.

Testing and Monitoring:

State-of-the-Art Signal Testing: Integrate cutting-edge signal testing equipment, including vector network analyzers and spectrum analyzers, to perform comprehensive signal integrity assessments. Develop an automated monitoring system to provide real-time alerts for any deviations from the established signal parameters.

Protection Against Physical Damage:

Advanced Protective Mechanisms: Integrate advanced protective mechanisms, such as impact-resistant cable conduits and reinforced cable jackets, to safeguard against physical damage. Implement strain relief systems using state-of-the-art cable grip technologies.

Documentation:

Comprehensive Record-Keeping: Establish an intricate documentation system that records not only cable installation details but also maintenance activities, inspections, and any troubleshooting undertaken. Utilize digital tools for documentation storage and retrieval efficiency.

Upgrades and Replacements:

Proactive Technology Integration: Stay at the forefront of technological advancements in cable design and functionality. Consider periodic assessments to evaluate the feasibility of integrating new cable technologies that offer enhanced performance or efficiency.

Immediate Replacement Protocols: Develop a responsive protocol for the immediate replacement of any cables exhibiting signs of degradation or failure, with a focus on minimizing downtime and potential data loss.

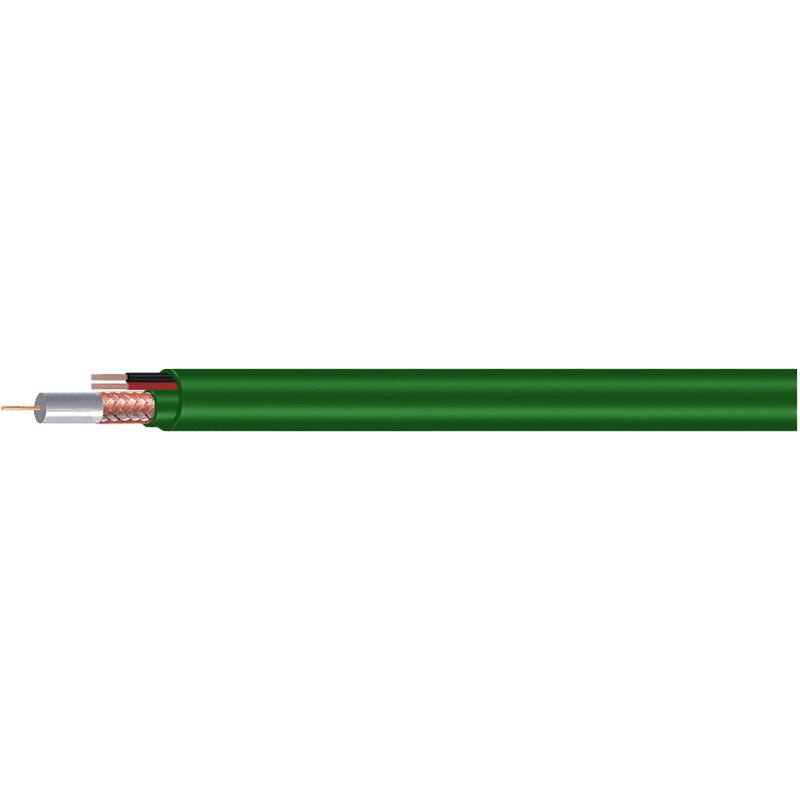

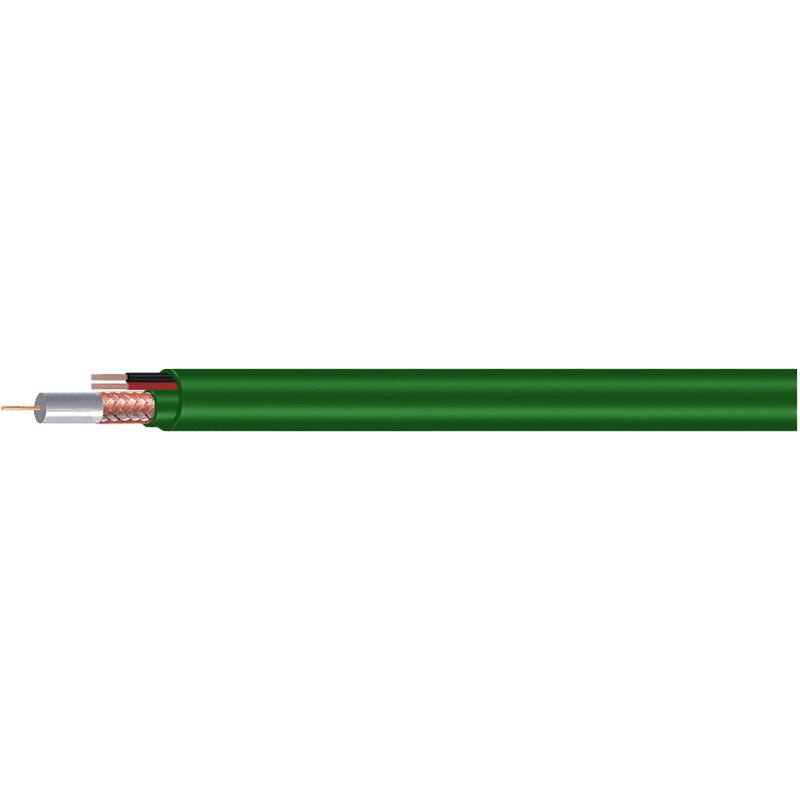

KX6 KX7 With Power Solid CCTV Camera Coaxial Cable

KX6 KX7 With Power Solid CCTV Camera Coaxial Cable